Until last year, Tull Farms based in Seaford, Delaware, sold its grain at harvest to several local elevators located within a 10-mile radius. A new grain system, completed in time for the 2021 harvest, has opened up new marketing opportunities and supported expansion of the operation.

“We were looking to grow our farm,” said Brian Tull, who runs the corn, soybean and wheat operation with his father, Ben. “We purchased 300 acres last year and picked up 300 rented acres the year before that. You can grow acre-wise, but I wanted more flexibility to harvest and sell grain when I wanted to. I also like being able to offer a higher-quality product by conditioning and drying my own grain.”

The new system, designed and installed by GSI’s Delmarva dealer, Westwood Farms, Inc., included two 48-foot diameter dry grain storage bins, each with 80,000 bushels of storage capacity, and two 15,000-bushel capacity bins for storing wet grain.

There’s also the TopDry high-efficiency, high-capacity system, which has an upper compartment for drying grain. Once dried, the grain is dumped into the holding area below for storage of up to 32,549 bushels. A smaller cooling/aeration fan captures heat from the previously dried grain and pushes it upward to help dry the next load.

Other components of the grain system include a 5,600 bushel-per-hour drag pit, a 6,000 bushel-per-hour, 113-foot-tall elevator for moving grain and a building that houses a grain scale, control room and other equipment. The system layout supports quick unloading and loading of grain.

Last season, Tull delivered some of his grain during harvest to the local elevators for use as chicken feed, which freed up space to store and dry additional grain on his farm. That allowed him to hold the rest to market during the winter and take advantage of higher grain prices. “We captured a better basis by storing grain through the winter rather than selling it at harvest, which improved our cash flow. It also opened new marketing opportunities,” he said.

For example, Tull was able to sell some soybeans on the export market for the first time. “We never could have done that before. Without enough storage, we could not have taken advantage of that opportunity.”

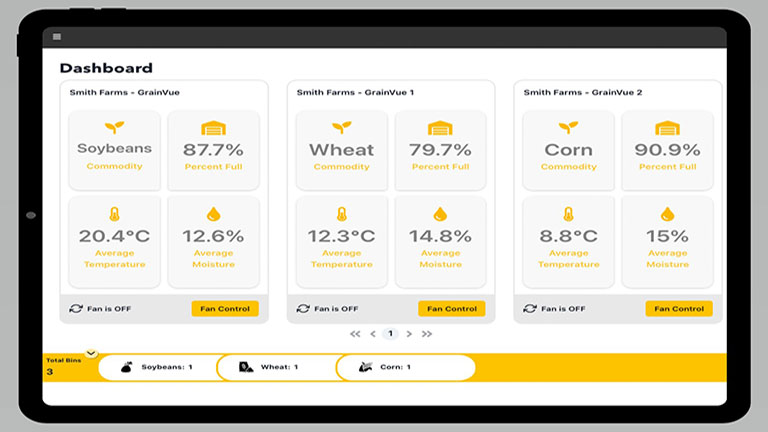

The new grain system is also fully automated. The TopDry unit offers remote monitoring and control. Stored grain is monitored continuously for moisture content using temperature cables, with aeration fans activated as needed to eliminate shrink and maintain grain condition in the bins.

Tull had an electrician install additional controls for other functions, such as operating the grain elevator and opening slide gates to discharge grain from bins and hopper tanks. “I can monitor and control the system from literally anywhere in the world,” he said.

Bruce Esham, president of the Westwood Farms dealership, noted that the system was also designed for future expansion. “The plan is to add another 80,000-bushel tank and a drag conveyor in the next couple of years,” he said. “Brian’s goal is to keep expanding. He sees the value of drying and storing his own grain.”

Tull said his operation, now 2,000 acres in size, is poised for continued growth. “With more revenue, I can pay off the new grain system and put that money back into our business. And that will give us the ability to grow even more.”