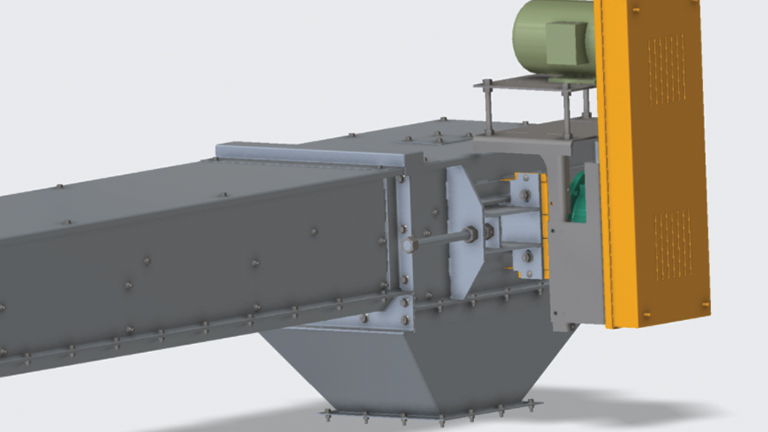

Chain Conveyors

GSI Select IS™ Kleen-Drag Conveyors

Chain Conveyors

Highlights

- Available exclusively as the Select IS™ model.

- Perfect solution in applications where cross-contamination is a primary concern, such as conveying feed products, or other sensitive commodities.

- Combine a unique trapezoidal trough shape to ensure positive clean-out with the same heavy-duty and maintenance-friendly features as the rest of the Select™ line of chain conveyors.

Built to Perform

Head Section

- Dodge® Imperial pillow block bearings standard on all sizes, supplied with full-coverage safety guarding

- Corrosion-resistant ACME threaded chain take-up system located on head section as standard

- ½” thick slotted edge machined UHMW shaft seals on all sizes keep dust in and weather out

- 7 gage side panels (4.55mm) standard on all sizes

- Flame-cut, hardened steel sprockets. Split hubs standard on all Kleen-Drag conveyors

- Head shafts are turned ground and polished

- Companion mating flanges available for all sizes

Intermediate Section

- Standard 10 gauge (3.41mm) intermediate trough sides

- Abrasion resistant steel wear liners with recessed fasteners for removal or replacement

- Fixture assembled for squareness to ensure accurate alignment and ease of installation

- Welded 2” structural steel angle flanges to provide rigidity and accurate alignment

- Side-mounted AR steel rail return (level sections) and full-width AR steel pan return (inclined sections) standard

- 3 standard cover styles to meet any need and ensure weather-tight operation

- Bolted removable bottom construction

Chain Features

- Steel Bushed Roller (SBR) and Welded Mill (WM) chains available to suit any application

- Multiple chain specs available in most box sizes to better suit conveyors of all lengths

- UHMW flight pads prevent steel-to-steel contact with Nylon optional for extremely abrasive materials

- Steel backer plates included on larger sizes and heavier chains to improve durability

Tail Section

- Fixed contoured tail sections ensure complete and consistent clean-out

- 7 gage side panels (4.55mm) standard on all sizes

- Flame-cut, hardened steel sprockets

- Split hubs standard on all Kleen-Drag conveyors

- Tail shafts are turned ground and polished

- Externally mounted pillow block bearings are standard on all sizes

Specifications

Click + to expand.

CAPACITIES (BPH)

| Size (WxH) | 1* | 100* | 110* | 120* | 130* | 140* | 150* | 160* | 170* | 180* |

|---|---|---|---|---|---|---|---|---|---|---|

| 9″x12″ | 23 | 2,296 | 2,525 | 2,755 | 2,984 | 3,214 | 3,443 | 3,673 | 3,903 | 4,132 |

| 12″x12″ | 31 | 3,105 | 3,416 | 3,727 | 4,037 | 4,348 | 4,658 | 4,969 | 5,279 | 5,590 |

| 16″x12″ | 42 | 4,185 | 4,604 | 5,022 | 5,441 | 5,859 | 6,278 | 6,696 | 7,115 | 7,533 |

| 16″x14″ | 47 | 4,654 | 5,119 | 5,585 | 6,050 | 6,516 | 6,981 | 7,446 | 7,912 | 8,377 |

| 21″x14″ | 62 | 6,150 | 6,765 | 7,380 | 7,995 | 8,610 | 9,225 | 9,840 | 10,455 | 11,070 |

| 14″x20″ | 65 | 6,487 | 7,136 | 7,785 | 8,433 | 9,082 | 9,731 | 10,379 | 11,028 | 11,677 |

| 16″x20″ | 74 | 7,433 | 8,176 | 8,920 | 9,663 | 10,406 | 11,149 | 11,893 | 12,636 | 13,379 |

| 20″x20″ | 93 | 9,325 | 10,257 | 11,190 | 12,122 | 13,055 | 13,987 | 14,920 | 15,852 | 16,784 |

| 26″x20″ | 122 | 12,162 | 13,379 | 14,595 | 15,811 | 17,027 | 18,243 | 19,460 | 20,676 | 21,892 |

| 32″x20″ | 150 | 15,000 | 16,500 | 18,000 | 19,500 | 21,000 | 22,500 | 24,000 | 25,500 | 27,000 |

*Conveyor speed in feet per minute.

Capacities calculated with no side liners, thicker side liners will reduce capacity.

DIMENSIONS (IN.)

| Box Size (Width x Height) | Vertical Offset | Overall Width | Overall Height* | Grain Depth | Head Length | Discharge Length | Tail Length | Y-Style Bypass Height* | Y-Style Bypass Width | Y-Style Bypass Height* | V-Style Bypass Width | Dump Hopper Height* | Dump Hopper Width |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A x B | B1 | C | D | E | F | G | H | I | J | K | L | M | N |

| 9″x12″ | 2 | 13 | 16.39 | 8.06 | 36 | 36 | 21 | 24.55 | 25 | 24.55 | 50 | 32.80 | 54.50 |

| 12″x12″ | 2 | 16 | 16.47 | 8.06 | 36 | 36 | 21 | 26.05 | 28 | 26.05 | 56 | 32.80 | 54.50 |

| 16″x12″ | 2 | 20 | 16.58 | 8.06 | 36 | 36 | 21 | 28.05 | 32 | 28.05 | 64 | 32.80 | 54.50 |

| 16″x14″ | 2 | 20 | 18.58 | 8.94 | 36 | 36 | 21 | 30.05 | 32 | 30.05 | 68 | 39.93 | 58.50 |

| 21″x14″ | 2 | 25 | 18.71 | 8.94 | 36 | 36 | 21 | 32.55 | 37 | 32.55 | 78 | 39.93 | 58.50 |

| 14″x20″ | 2 | 18 | 24.53 | 14.13 | 36 | 36 | 25 | 35.05 | 38 | 35.05 | 76 | 45.93 | 66.00 |

| 16″x20″ | 2 | 20 | 24.58 | 14.13 | 36 | 36 | 25 | 36.05 | 40 | 36.05 | 80 | 45.93 | 66.00 |

| 20″x20″ | 2 | 24 | 24.68 | 14.13 | 36 | 36 | 25 | 38.05 | 44 | 38.05 | 88 | 45.93 | 66.00 |

| 26″x20″ | 2 | 30 | 24.84 | 14.13 | 36 | 36 | 25 | 41.05 | 50 | 41.05 | 100 | 45.93 | 66.00 |

| 32″x20″ | 2 | 36 | 25.00 | 14.13 | 36 | 36 | 25 | 44.05 | 56 | 44.05 | 112 | 45.93 | 66.00 |

* Based on 3/16 bottom liner and lapped covers, heavier bottom liners and alternate cover styles will increase this dimension.