Monitoring stored grain isn’t a new idea. For years, farmers have climbed the ladder for a quick look or a smell test. On many farms, cable systems have taken the place of these methods, meaning fewer trips up and down the ladder and less time spent taking samples, checking moisture and hoping there aren’t any hot spots spoiling grain they can’t see. Keeping a close eye on the temperature, moisture and inventory lets producers pursue higher premiums and get the most out of every bushel harvested.

What stored grain management systems do

Today, stored grain management tools can do more than just provide farmers with up-to-date moisture and temperature data. They can also help them keep track of inventory and receive alerts about the condition of their grain alongside the information they need to correctly set their heaters and fans to keep their grain in ideal condition.

The best systems can also automate those management processes so that farmers who want to dry or store grain can do so efficiently and without constantly watching outside temperature and moisture factors.

GSI’s GrainVue fits the bill

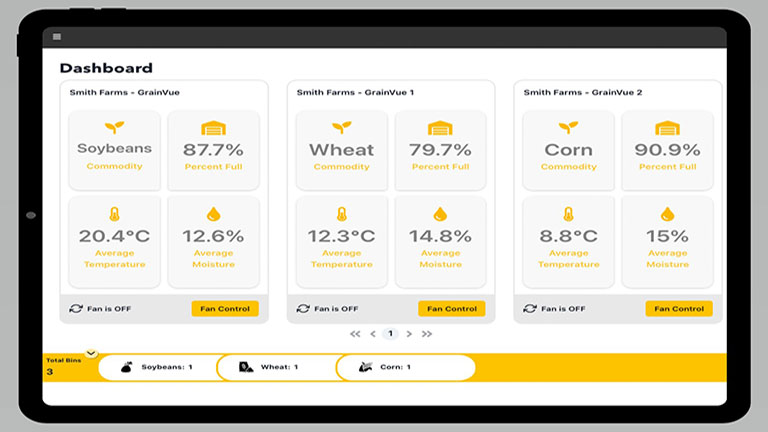

GSI’s GrainVue is one of these premier stored grain management systems. GrainVue uses an easy-to-understand dashboard alongside cloud connectivity to let growers assess and make decisions about their stored grain, no matter where they are. With 24/7 alerts and updates, farmers can manage the system via a smartphone, tablet or desktop computer.

In addition to the standard monitoring capabilities offered by stored grain management systems, such as moisture, temperature and inventory, the GrainVue system includes automated aeration management that farmers can use to reach various goals.

- If grain needs to dry down: Farmers can often benefit from harvesting their grain at higher than ideal moisture levels, as it may allow for an earlier and more timely harvest. The automation in the GrainVue system will maximize the effectiveness of a natural air drying system by only running the fans when the outside conditions are favorable, helping save energy.

- If grain needs to cool off: Farmers want to get the temperature of their grain down as quickly as possible once it exits the dryer. Many farmers do this manually, turning on the fans at night to take advantage of the cooler nighttime air temperatures, then manually turning fans off in the daytime.

With GrainVue and a connected weather station, a farmer can set parameters and automate the fans, turning them on and off to maximize the cooling capability. This automation helps save time and energy by running the fans only when needed. - If grain needs to rehydrate: Soybeans can be rehydrated when harvested too dry by bringing the moisture up to the market standard of 13%. Farmers can achieve this by operating fans during periods of higher relative humidity. GrainVue and a weather station can automate this process, turning fans on and off when the outside relative humidity reaches a set point and pulling moist air into the bin until the beans reach the desired moisture level.

On a 60-bushel-per-acre yield, harvesting soybeans at 9% moisture content, rather than 13%, equals 2.7 bushels of lost weight per acre. At $9 per bushel, that's $24.30 per acre. Increasing the moisture content from 9% to 13% would increase the quantity of soybeans by 1,528.5 bushels. At $9 per bushel, that’s worth $13,756.50, more than the cost of operating the fan. - If grain just needs to store well: When sunlight hits a grain bin, it begins to warm up. The significant temperature differential can cause condensation inside bins as outside temperatures increase, leading to grain spoilage. GrainVue can slowly warm up the grain with aeration to keep the grain temperature within 10 degrees of the outside temperature. This is important if you plan to store grain into the summer months.

GSI GrainVue is just the beginning

For 50 years, GSI has brought unprecedented expertise to the grain conditioning space by developing the products farmers need to protect their grain investment from the field to the elevator and everywhere in between. Who better to help farmers quickly and easily manage and protect their grain than the company that designs and delivers the industry-leading grain storage systems that farmers know and trust.

Monitoring grain quality isn’t new. But launching GrainVue is the foundation of GSI’s comprehensive grain conditioning platform, making it easier for farmers to take their operation’s storage success to the next level.