If you're leaving money on the table by harvesting soybeans too dry, you're not alone. Every year, farmers lose bushels and profit because beans are harvested with moisture levels below the market standard of 13%. But what if you could fix that after harvest, right in the bin?

That’s where GSI’s GrainVue system comes in. While it's known for automating grain monitoring, one of its most overlooked superpowers is rehydration – bringing too-dry soybeans back up to spec using smart fan control and real-time weather data. It’s a simple idea with significant returns and could make a major difference in your bottom line.

“With round-the-clock monitoring, automated aeration and an intuitive interface, GrainVue makes it simple to manage your stored grain,” said Greg Trame, sales director at GSI. “Farmers can trust their grain is staying in top condition, whether it’s cooling, drying, storing or rehydrating.”

Smart grain management starts in the bin

GSI’s GrainVue system gives farmers more control – and more confidence – after harvest. It uses sensors placed throughout the grain bin to collect real-time data on grain temperature, moisture and CO₂ levels, then pairs that data with local weather conditions from an on-site weather station.

The system analyzes that information continuously and automates fan operation to match your goals. Whether you’re drying, cooling, holding or rehydrating, GrainVue decides when conditions are right and runs the fans accordingly – only when it’s effective and never when it’s wasteful.

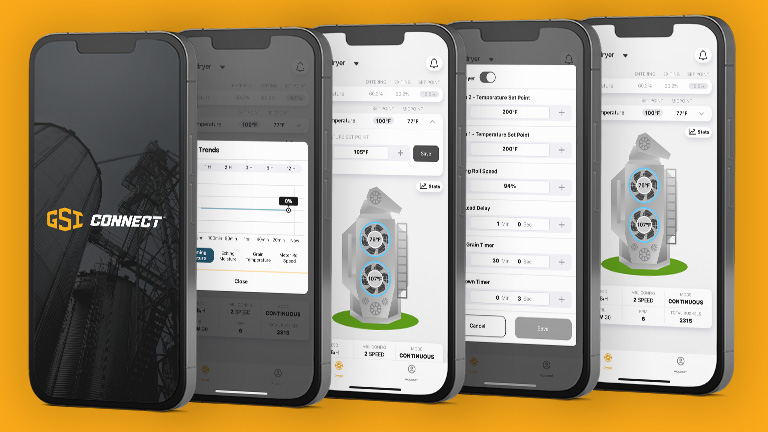

It’s also cloud-based, allowing you to monitor everything from your smartphone, tablet or computer. You receive alerts if conditions change and updates as your grain approaches your target specifications.

“GrainVue uses temperature and moisture cables inside the bin to track crop conditions,” said Trame. “That data is sent to the cloud, so you can check it anytime from your phone, tablet or computer – giving you the insight you need to make smart, timely decisions for safe storage.”

The rehydration advantage

When farmers harvest soybeans, the moisture content can be lower than ideal, sometimes as low as 9%. Dry soybeans weigh less, and since they’re sold by weight, it’s a straight hit to your paycheck.

Let’s say you harvest 50,000 bushels at 9% moisture instead of 13%. That’s roughly a 4% weight difference, which translates to approximately 2,000 bushels lost. At $10 per bushel, that’s more than $20,000 in missed revenue – money you could recover with a bin-based rehydration strategy.

GrainVue enables you to do exactly that by utilizing ambient humidity to restore soybeans to market-standard moisture levels safely. The system constantly monitors the outside air’s equilibrium moisture content and only runs the fans when the conditions are ideal for moisture gain.

There’s no guesswork, no over-hydrating and no wasted electricity. You choose your target moisture, and the system works around the clock – quietly and efficiently – to help you achieve it.

“When the grain market takes a turn, having a system like GrainVue can make the difference in still turning a profit,” said Ben Van Roekel, Iowa farmer and GSI customer. “It’s basically giving your bin a brain, automating the process to get you the best grain conditions in the bin, so you aren’t having to manually monitor.”

CO₂ monitoring is the early warning you didn’t know you needed

GrainVue doesn’t just help you add moisture back in – it also enables you to maintain grain quality while doing it. One of the most powerful features in the system is CO₂ monitoring, which acts like an early warning system for grain spoilage.

“Measuring CO₂ is crucial – it’s one of the earliest indicators of spoilage,” said Trame. “Farmers know the smell they’re watching for when they check a bin, and with GrainVue, we’ve essentially automated that smell test by tracking carbon dioxide levels.”

Here’s how it works: when grain starts to go bad, whether from mold, insects or crusting, it gives off carbon dioxide. By monitoring CO₂ levels in the bin, GrainVue can detect these problems before you notice a temperature spike or a shift in moisture.

That’s especially important when rehydrating soybeans, since you’re intentionally introducing some moisture. With CO₂ alerts in place, you’ll know right away if something’s off, long before it turns into a full-blown spoilage issue.

Automation you can trust, even during the busy season

Harvest season is hectic. You’re juggling equipment, labor, weather windows and hauling schedules. GrainVue takes one major task off your plate by automating grain conditioning and giving you remote access to bin status. Whether you're out in the field or miles away, you can check fan activity, bin temperatures, moisture targets and grain levels – all from your phone.

It also keeps records automatically, which helps with traceability, compliance and performance analysis year over year.

The bottom line

GSI’s GrainVue system is more than just a grain monitoring tool – it’s a revenue protection strategy. Its ability to rehydrate soybeans harvested too dry gives farmers a second chance at achieving full market value. Add in CO₂ monitoring, fan automation and remote access, and you’ve got a system that works as hard as you do, without needing constant supervision.

Whether you’re managing one bin site or a dozen, GrainVue helps you protect your crop, your time and your bottom line.