Additional Markets

In addition to grain and feed markets, InterSystems, the brand known as a worldwide manufacturer of bulk material handling equipment and industrial sampling systems, is found on a full range of products in support of other industries.

Sales and Service

Check this area often for updated manuals, software updates and limited time offers.

About Us

GSI supports agriculture around the globe with the most extensive global manufacturing footprint and dealer network in our industry. We bring our customers local solutions with global expertise.

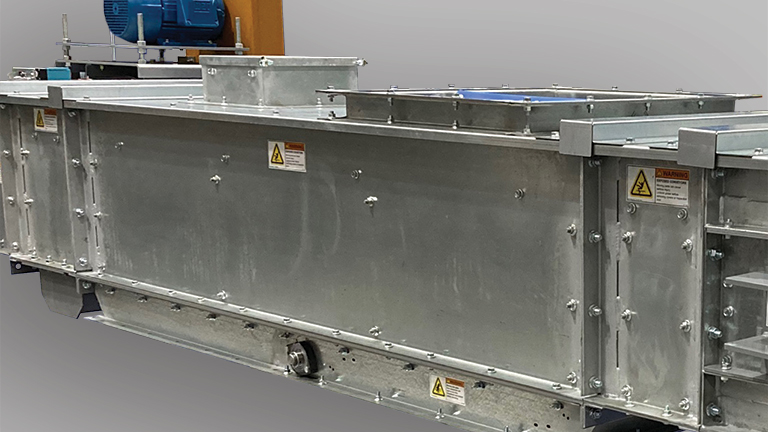

GSI Select™ En-Masse Chain Conveyors

The Perfect Conveyor for Your Project

GSI Select™ En-Masse Chain Conveyors

The Perfect Conveyor for Your Project

Highlights

- Limitless custom configurations with the right sizes, layouts, capacities, options and accessories – it’s your choice and it’s almost all standard.

- Commercial-grade options such as wear liners and bearings.

- We’ve taken the best design elements and combined them into one platform. Superior craftsmanship, commercial-grade dependability and easy maintenance that for decades of reliable and profitable service.

- Designed for your application, with greater flexibility and a wider selection of features and options.

- GSI Select IS comes standard with split sprocket for easier service, higher-end roller bearings and class II drives with class III upgrades. Hot dip galvanize or stainless steel finish, our most durable AR500 liner and S-Path alignment are all exclusive options.

Easily create and customize the perfect conveyor for your project.

GSI's top-of-the-line conveyor is loaded with premium features and exclusive options.

Built to Perform

Head Section

- Dodge® pillow block bearings standard on all sizes, supplied with full-coverage safety guarding

- ½” thick slotted edge machined UHMW shaft seals on all sizes keep dust in & weather out

- 7 gage side panels (4.55mm) standard on all sizes

- Flame-cut, hardened steel sprockets. Split hubs standard on Select IS, and available on Select

- Head shafts are turned ground and polished

- Companion mating flanges and discharge transitions available for all sizes

Intermediate Section

- Standard 10 gauge (3.41mm) intermediate trough sides

- Abrasion resistant steel wear liners with recessed fasteners for removal or replacement

- Fixture assembled for squareness to ensure accurate alignment and ease of installation

- Welded 2” structural steel angle flanges to provide rigidity and accurate alignment

- AR steel slide rail or UHMW roller return available on all sizes

- 3 standard cover styles to meet any need & ensure weather-tight operation

- Bolted removable bottom construction

Chain Features

- Steel Bushed Roller (SBR) & Welded Mill (WM) chains available to suit any application

- Multiple chain specs available in most box sizes to better suit conveyors of all lengths

- UHMW flight pads prevent steel-to-steel contact with Nylon optional for extremely abrasive materials

- Optional return cups for intermediate discharge or reversing applications to assist with clean-out

Tail Section

- Dodge® pillow block bearings standard on all sizes, supplied with full-coverage safety guarding

- Corrosion-resistant ACME threaded chain take-up system with machined UHMW shaft seals

- 7 gage side panels (4.55mm) standard on all sizes

- Flame-cut, hardened steel sprockets. Split hubs standard on Select IS, and available on Select

- Tail shafts are turned ground and polished

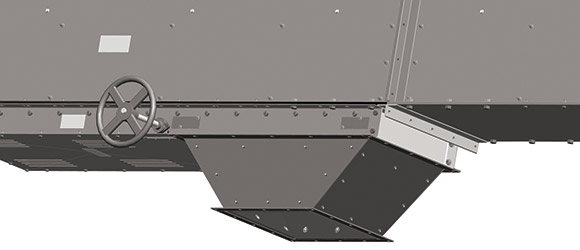

Discharge Gate

- Flush style design standard for both intermediate & head gates to minimize cross-contamination

- Chain carry over bars are laser cut into 3/8" abrasion resistant plate bottom for superior alignment

- Beveled edges ensure smooth operation

- Available in inline or crosscut styles

- Options include factory mounting and electric drives

Specifications

Click — to collapse sections.

CAPACITIES (BPH)

| Size (WxH) | 1* | 100* | 110* | 120* | 130* | 140* | 150* | 160* | 170* | 180* |

|---|---|---|---|---|---|---|---|---|---|---|

| 9"x12" | 21 | 2,109 | 2,320 | 2,531 | 2,742 | 2,953 | 3,164 | 3,375 | 3,586 | 3,797 |

| 12"x12" | 28 | 2,812 | 3,094 | 3,375 | 3,656 | 3,937 | 4,219 | 4,500 | 4,781 | 5,062 |

| 16"x12" | 37 | 3,750 | 4,125 | 4,500 | 4,875 | 5,250 | 5,625 | 6,000 | 6,375 | 6,750 |

| 16"x14" | 47 | 4,687 | 5,156 | 5,625 | 6,094 | 6,562 | 7,031 | 7,500 | 7,969 | 8,437 |

| 21"x14" | 62 | 6,152 | 6,768 | 7,383 | 7,998 | 8,613 | 9,228 | 9,844 | 10,459 | 11,074 |

| 14"x20" | 66 | 6,562 | 7,219 | 7,875 | 8,531 | 9,187 | 9,844 | 10,500 | 11,156 | 11,812 |

| 16"x20" | 75 | 7,500 | 8,250 | 9,000 | 9,750 | 10,500 | 11,250 | 12,000 | 12,750 | 13,500 |

| 20"x20" | 94 | 9,375 | 10,312 | 11,250 | 12,187 | 13,125 | 14,062 | 15,000 | 15,937 | 16,875 |

| 26"x20" | 122 | 12,187 | 13,406 | 14,625 | 15,844 | 17,062 | 18,281 | 19,500 | 20,719 | 21,937 |

| 32"x20" | 150 | 15,000 | 16,500 | 18,000 | 19,500 | 21,000 | 22,500 | 24,000 | 25,500 | 27,000 |

| 26"x26" | 164 | 16,377 | 18,014 | 19,652 | 21,290 | 22,928 | 24,565 | 26,203 | 27,841 | 29,478 |

| 32"x26" | 202 | 20,156 | 22,172 | 24,187 | 26,203 | 28,218 | 30,234 | 32,250 | 34,265 | 36,281 |

| 32"x32" | 260 | 26,049 | 28,654 | 31,259 | 33,864 | 36,468 | 39,073 | 41,678 | 44,283 | 46,888 |

| 36"x32" | 293 | 29,305 | 32,235 | 35,166 | 38,096 | 41,027 | 43,957 | 46,888 | 49,818 | 52,749 |

* Conveyor speed in feet per minute.

Capacities calculated with no side liners, thicker side liners will reduce capacity.

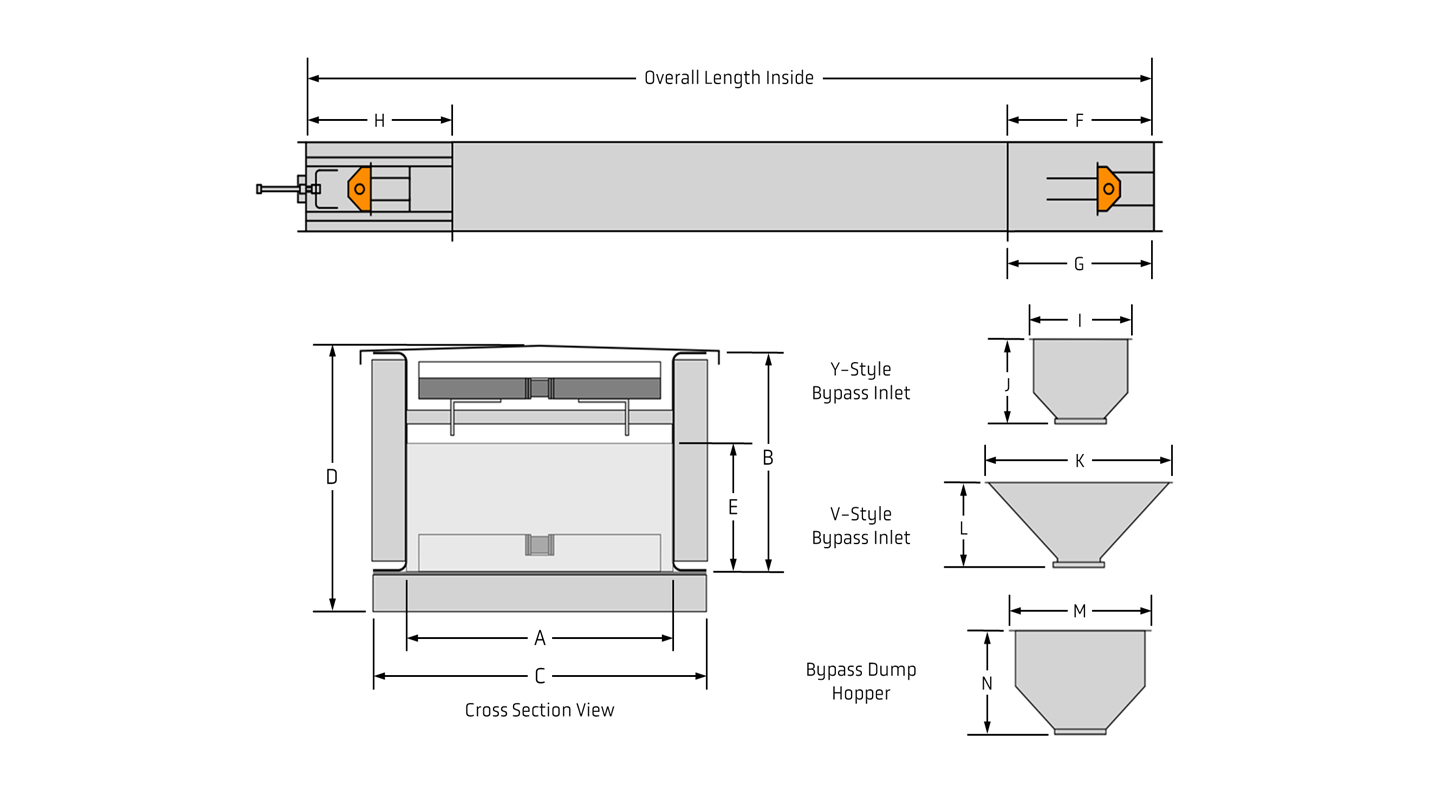

DIMENSIONS (IN.)

| Box Size (width x height) | Overall Width | Overall Height* | Grain Depth | Head Length | Discharge Length | Tail Length (Standard) | Tail Length (Clean-out) | Y-Style Bypass Height* | Y-Style Bypass Width | Y-Style Bypass Height* | V-Style Bypass Width | Dump Hopper Height* | Dump Hopper Width |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A x B | C | D | E | F | G | H | H | I | J | K | L | M | N |

| 9"x12" | 13 | 14.53 | 7.00 | 36 | 36 | 36 | 24 | 22.69 | 25 | 22.69 | 50 | 30.94 | 54.50 |

| 12"x12" | 16 | 14.61 | 7.00 | 36 | 36 | 36 | 24 | 24.19 | 28 | 24.19 | 56 | 30.94 | 54.50 |

| 16"x12" | 20 | 14.71 | 7.00 | 36 | 36 | 36 | 24 | 26.19 | 32 | 26.19 | 64 | 30.94 | 54.50 |

| 16"x14" | 20 | 16.71 | 8.75 | 36 | 36 | 36 | 24 | 28.19 | 32 | 28.19 | 68 | 38.06 | 58.50 |

| 21"x14" | 25 | 16.84 | 8.75 | 36 | 36 | 36 | 24 | 30.69 | 37 | 30.69 | 78 | 38.06 | 58.50 |

| 14"x20" | 18 | 22.66 | 14.00 | 36 | 36 | 36 | 24 | 33.19 | 38 | 33.19 | 76 | 44.06 | 66.00 |

| 16"x20" | 20 | 22.71 | 14.00 | 36 | 36 | 36 | 24 | 34.19 | 40 | 34.19 | 80 | 44.06 | 66.00 |

| 20"x20" | 24 | 22.82 | 14.00 | 36 | 36 | 36 | 24 | 36.19 | 44 | 36.19 | 88 | 44.06 | 66.00 |

| 26"x20" | 30 | 22.97 | 14.00 | 36 | 36 | 36 | 24 | 39.19 | 50 | 39.19 | 100 | 44.06 | 66.00 |

| 32"x20" | 36 | 23.13 | 14.00 | 36 | 36 | 36 | 24 | 42.19 | 56 | 42.19 | 112 | 44.06 | 66.00 |

| 26"x26" | 30 | 28.97 | 18.81 | 48 | 36 | 48 | 42 | 45.19 | 50 | 45.19 | 112 | 54.19 | 66.00 |

| 32"x26" | 36 | 29.13 | 18.81 | 48 | 36 | 48 | 42 | 48.19 | 56 | 48.19 | 124 | 54.19 | 66.00 |

| 32"x32" | 36 | 35.13 | 24.31 | 48 | 36 | 48 | 42 | 56.19 | 60 | 56.19 | 140 | 59.19 | 66.00 |

| 36"x32" | 40 | 35.24 | 24.31 | 48 | 36 | 48 | 42 | 56.19 | 60 | 56.19 | 144 | 59.19 | 66.00 |

* Based on 3/16 bottom liner and lapped covers, heavier bottom liners and alternate cover styles will increase this dimension.