Additional Markets

In addition to grain and feed markets, InterSystems, the brand known as a worldwide manufacturer of bulk material handling equipment and industrial sampling systems, is found on a full range of products in support of other industries.

Sales and Service

Check this area often for updated manuals, software updates and limited time offers.

About Us

GSI supports agriculture around the globe with the most extensive global manufacturing footprint and dealer network in our industry. We bring our customers local solutions with global expertise.

Modular Tower Dryers

Modular construction for speed of installation

Modular Tower Dryers

Modular construction for speed of installation

Highlights

- Drying capacities up to 1,690 BPH dry and cool at 5 pt. removal.

- Easy heat recovery without uneven heat issues.

- Patented self cleaning divider floor and quiet operation with the fans located inside the grain column.

- Standard vacuum cool heat recovery.

- LP or natural gas.

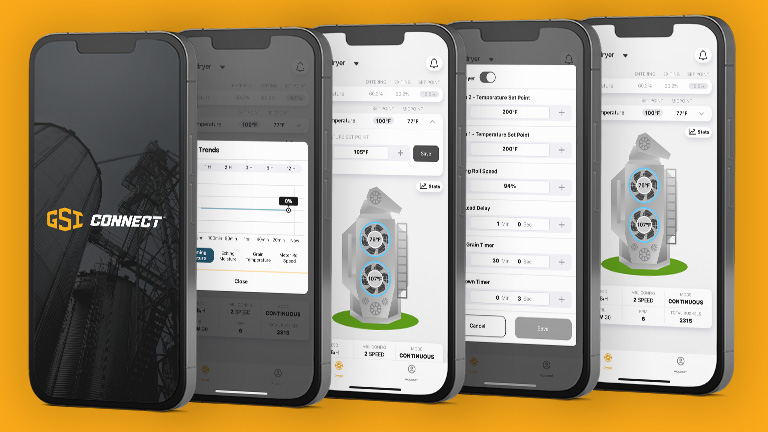

GSI Connect

Remote Dryer Management

Know your dryer a little less personally this harvest

Harvest is hectic. And the last thing you need is an extra trip to the dryer. With GSI Connect, you know your dryer is doing its job. So, you can stay where you are and keep doing yours.

- Control from anywhere

- See your dryer's status, moisture, temperature

- Adjust set points, stop your dryer and change unload speeds

- Monitor your dryer's performance and get alerts to reduce runtime and maximize profit

Getting Started is Easy

Best of all, portable dryers are just the beginning. GSI is working to make GSI Storage and Material Handling connect-ready too. So, with GSI Connect, you can put your entire grain system in your hands.

Built to Perform

Vision Controls

Vision controls offer simple operation, with an easy-to-read large color graphical touch display. Located on the dryer or remote with a few wires, these controls are design specifically for GSI grain dryers, giving you unmatched options and settings to get exactly what you need from your dryer control.

Modular Tower Dryer Exclusive

Adjustable Cooling Floor

The patented adjustable floor allows either 1/3 or 1/5 of the dryers column to be used for cooling, allowing for higher capacities in high moisture conditions or maximum cooling in more normal conditions as well as a higher exiting grain temperature to take advantage of cooling bins, increasing capacity and improving efficiency and grain quality.

Patented

Grain Inverters

Eliminate over-dried grain and maximize drying efficiency and quality. This patented system inverts all but the outside 2" (50.8 mm) of grain promoting higher test weights, maximum grain quality, and reduced fuel usage. The outside layer of wet grain is dried using the heat which would have otherwise escaped the dryer, keeping your operation energy efficient. A convenient clean-out door provides easy, quick maintenance.

Static Moisture Sampler

Improve your accuracy with the static moisture sampler. Debris guards ensure a trash-free sample and delivers a uniform representative sample to the test chamber. A blower system gently moves the grain out of the chamber, cleaning it each cycle. Get the most accurate results as the moisture reading used to monitor/calculate discharge grain moisture is only taken while the grain is static and not flowing.