Additional Markets

In addition to grain and feed markets, InterSystems, the brand known as a worldwide manufacturer of bulk material handling equipment and industrial sampling systems, is found on a full range of products in support of other industries.

Sales and Service

Check this area often for updated manuals, software updates and limited time offers.

About Us

GSI supports agriculture around the globe with the most extensive global manufacturing footprint and dealer network in our industry. We bring our customers local solutions with global expertise.

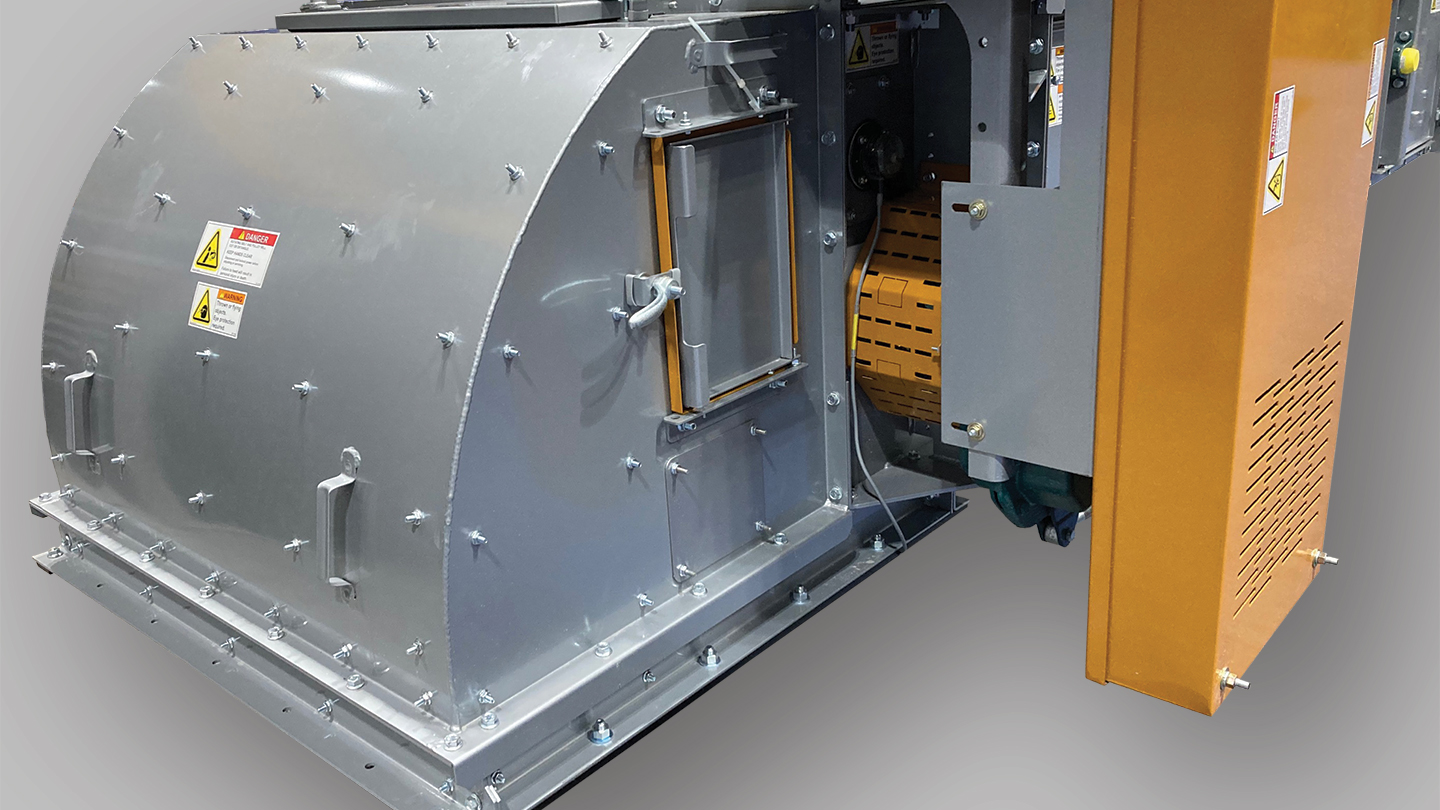

GSI Select Enclosed Belt Conveyors

Custom without Compromise

GSI Select Enclosed Belt Conveyors

Custom without Compromise

Highlights

- GSI has the perfect belt conveyor to fit your operation, easily customizable for your project.

- Precisely crafted with the highest quality materials and components to deliver performance you can count on.

- Ideal for long length runs.

- A clean, efficient, and gentle way to move grain.

- Requires less energy and lower maintenance than other conveyor types.

Easily create and customize the perfect conveyor for your project.

GSI's top-of-the-line conveyor is loaded with premium features and exclusive options.

Built to Perform

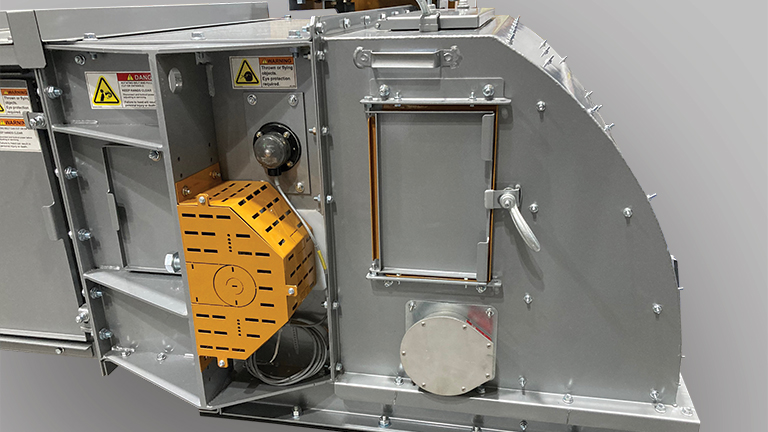

Head Section

- Dodge® Imperial pillow block bearings standard on all sizes, supplied with full-coverage safety guarding

- 7 ga. reinforced steel housing with 12 ga. removable lined hood

- Lagging inspection doors on both sides of the head allow service of lagging without breaking the belt

- 16”, 24”, 30” and 36” pulley diameters available, secured with XT tapered bushings

- Holz Slide-Lag® static conductive lagging on head pulleys for superior belt grip, long-life, and easy service Shafting of 1045 turned ground and polished steel

- Low profile style construction, and 2-way valve equipped heads optional

Intermediate Section

- External vertically mounted Dodge® pillow block ball bearings with safety caps standard

- Anti-static UHMW bottom liners, 1/4" thick, bolted in slots to allow for thermal expansion

- 10' intermediate sections with 5' clamp-on covers

- 45˚ idler rollers placed every 5'

- 12 ga. housing, with 7 ga. reinforcing vertical channels at the bearings

- Inspection doors at intermediate section next to head and tail section

- Optional 1/2" UHMW bottom liner

- Optional heavy-duty idlers

- Optional side service doors for roller removal

Tail Section

- Dodge® Imperial pillow block bearings standard on all sizes, supplied with full-coverage safety guarding

- 14" spiral wing type pulley with reloading rubber flippers at each end

- Plow assembly between belts to move spilled material to side reloaders. Adjustable with replaceable skirting

- 18", 24", 36" and 48" manual take-up with acme threads on take-up screws

- Shafting of 1045 turned ground and polished steel

- 3/16" thick take-up housing

- Swing-up tail shroud for easy, safe access to pulley

Loader and Belt

- Urethane lined loader (sides and rear), skirted, with matching spout angle frame

- Pivoting UHMW skirts with stops on the conveyor with multiple inlets

- Inspection door at the front of the loader

- Flexco splice, 140EE, belt pre-punched at both ends

- SOR-SC-FR rubber belting with tail reloading rubber flippers at splice

- Optional ceramic tile liners

Specifications

Click — to collapse sections.

CONVEYOR SPEED (FT/MIN.)*

| Capacity (BPH) | 24" | 30" | 36" | 42" | 48" | 54" |

|---|---|---|---|---|---|---|

| 8,000 | 400 | |||||

| 10,000 | 485 | |||||

| 12,000 | 582 | |||||

| 13,000 | 630 | 415 | ||||

| 14,000 | 447 | |||||

| 15,000 | 479 | |||||

| 20,000 | 640 | 466 | ||||

| 25,000 | 583 | 451 | ||||

| 30,000 | 700 | 541 | 435 | |||

| 35,000 | 631 | 508 | ||||

| 40,000 | 721 | 580 | 480 | |||

| 45,000 | 653 | 540 | ||||

| 50,000 | 725 | 600 | ||||

| 60,000 | 720 |

* Capacities calculated with material surcharge angle of 13˚, lower surcharge angle materials will see reduced capacities.

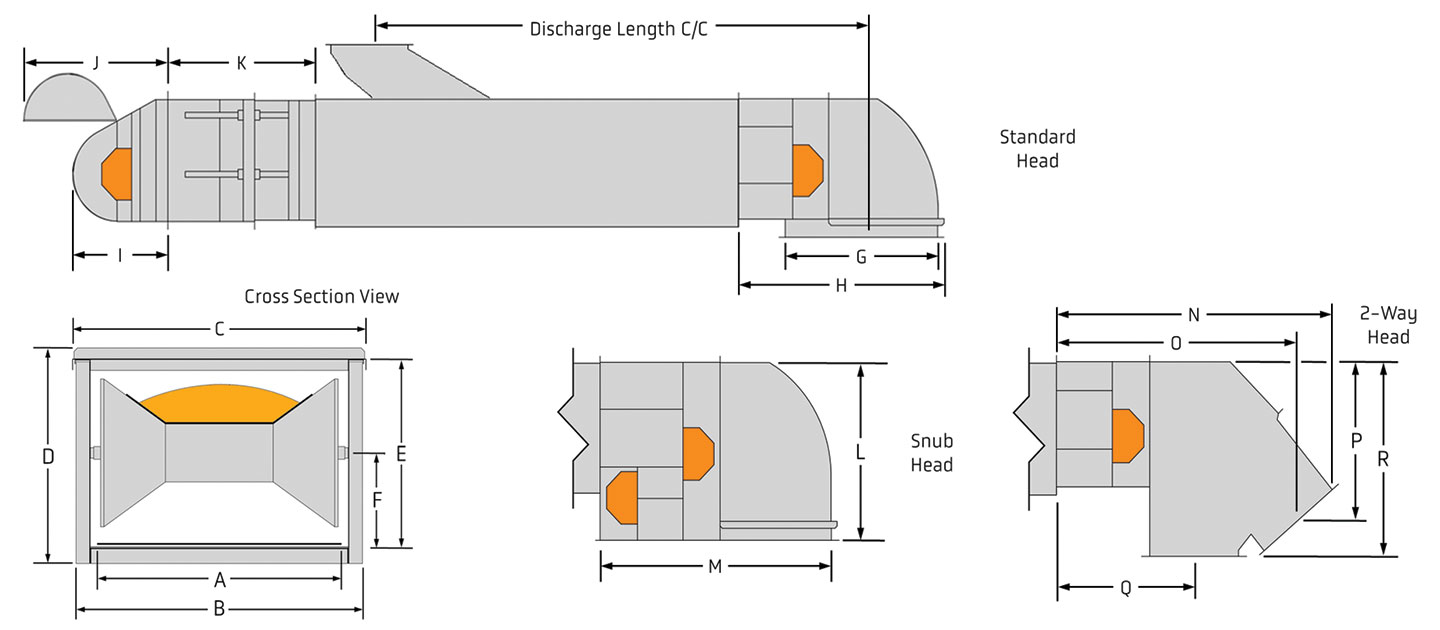

DIMENSIONS (IN.)

| Belt Width | Box Width | Overall Width | Overall Height | Box Height | Idler Height | Discharge Length | Std. Head Length | Tail Length | |

| Size | A | B | C | D | E | F | G | H | I |

| 24" | 24 | 31 | 32 | 29.625 | 26 | 13.5 | 36 | 49 | 23 |

| 30" | 30 | 37 | 38 | 29.625 | 26 | 13.5 | 36 | 49 | 23 |

| 36" | 36 | 43 | 44 | 29.625 | 26 | 13.5 | 36 | 49 | 23 |

| 42" | 42 | 49 | 50 | 29.625 | 26 | 13.5 | 36 | 49 | 23 |

| 48" | 48 | 55 | 56 | 29.625 | 26 | 13.5 | 36 | 49 | 23 |

| 54" | 54 | 61 | 62 | 29.625 | 26 | 13.5 | 36 | 49 | 23 |

| Tail Shroud Clearance | 24" Snub Head Height | 24" Snub Head Discharge | 2-Way Head Length | 1st Discharge Length | 1st Discharge Height | 2nd Discharge Length | 2nd Discharge Height | |

| Size | J | L | M | N | O | P | Q | R |

| 24" | 39 | 39 | 52 | 65 | 55 | 34 | 32 | 42 |

| 30" | 39 | 39 | 52 | 65 | 55 | 34 | 32 | 42 |

| 36" | 39 | 39 | 52 | 65 | 55 | 34 | 32 | 42 |

| 42" | 39 | 39 | 52 | 65 | 55 | 34 | 32 | 42 |

| 48" | 39 | 39 | 52 | 65 | 55 | 34 | 32 | 42 |

| 54" | 39 | 39 | 52 | 65 | 55 | 34 | 32 | 42 |

| Take-Up Length (K) | ||

| Size | Minimum | Maximum |

| 18" | 36.00 | 54.00 |

| 24" | 42.00 | 66.00 |

| 30" | 48.00 | 78.00 |

| 36" | 54.00 | 90.00 |

| 42" | 60.00 | 102.00 |

| 48" | 66.00 | 114.00 |

| 54" | 72.00 | 126.00 |

| 60" | 78.00 | 138.00 |